1.软件准备

(1)编程平台:Keil5

(2)CubeMX

2.硬件准备

(1)本此使用最小核心板STM32F103C8T6为例

(2)一个舵机:SG90或者MG996等均可

(3)ST-link 下载器

(4)杜邦线若干

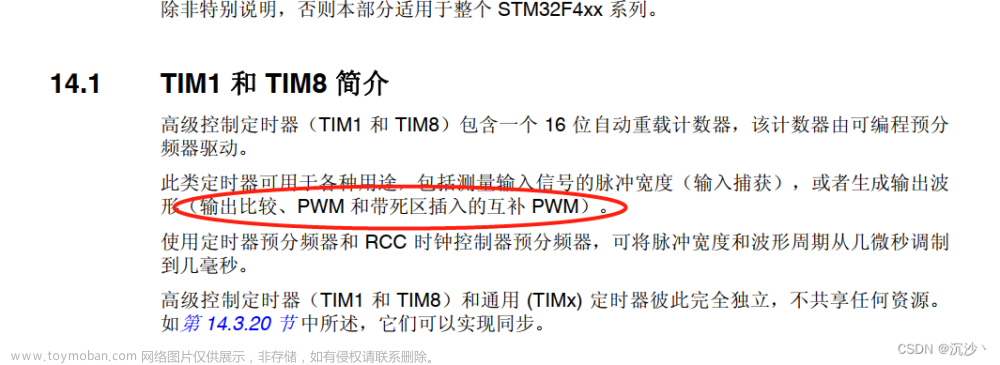

3.关于舵机控制原理

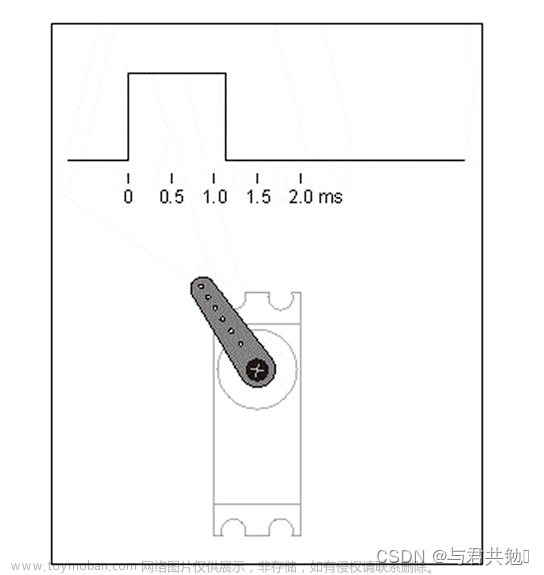

舵机的控制一般需要一个20ms左右的时基脉冲,该脉冲的高电平部分一般为0.5ms-2.5ms范围内的角度控制脉冲部分,总间隔为2ms。以180度角度伺服为例,那么对应的控制关系是这样的:

4.CubeMX配置

(1)打开STM32CubeMX

(2)新建项目

(2)选择所需要的芯片

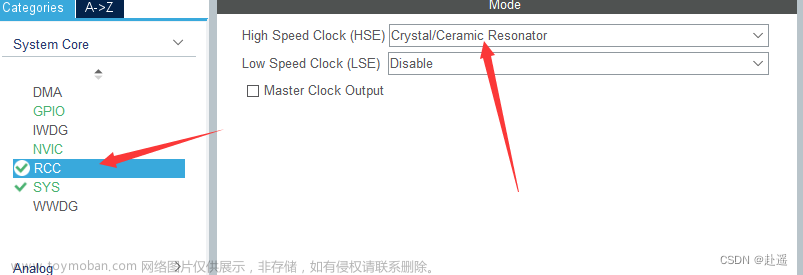

(3)配置RCC、SYS、时钟树

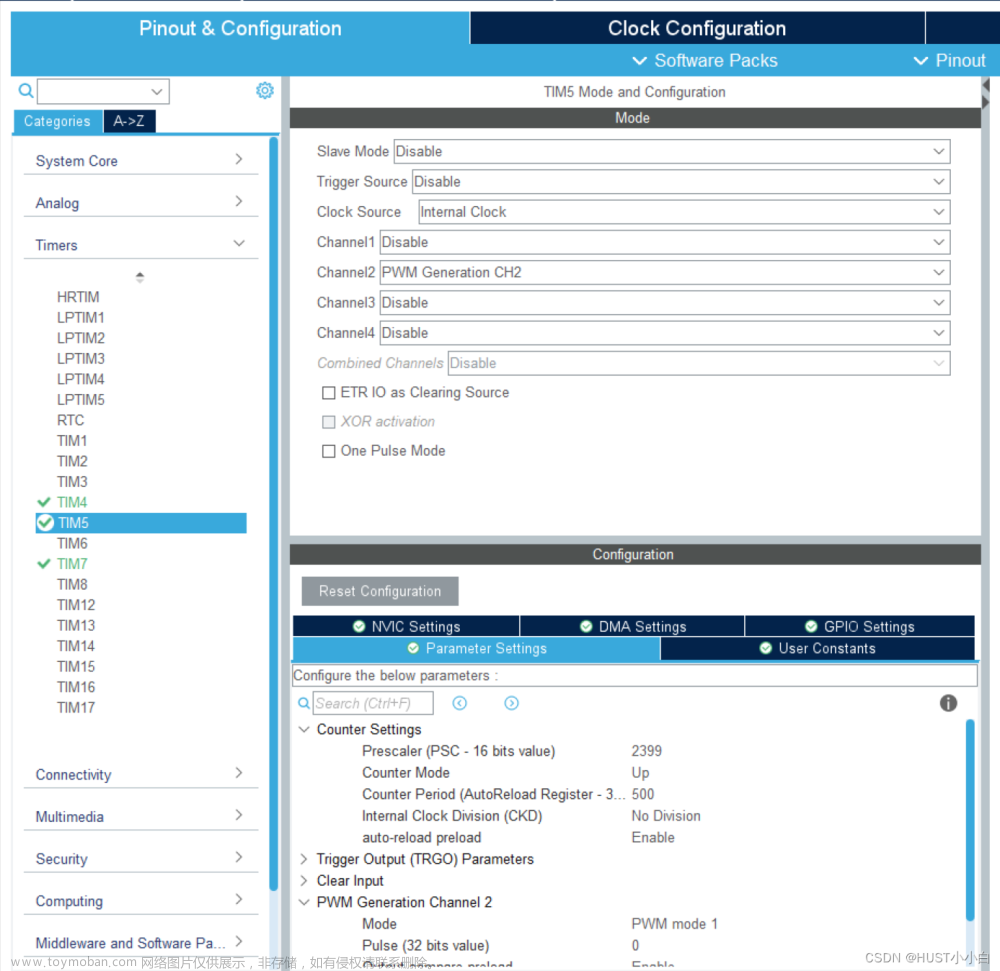

(4)配置定时器产生PWM波形

(4)配置定时器产生PWM波形

本次配置四个通道,可同时输出四路PWM信号

舵机控制需要一个20ms左右的时基脉冲,

查手册可知TIM3在APB1总线上

时钟配置时APB1的时钟为72MHz

此时产生PWM波形频率:72M / (72-1) / (20000-1) = 50HZ

波形周期:1 / 50 = 20ms

可配置舵机初始值,此次配置为500

通过计算可得500/(19999+1)=0.5ms/20ms 则对应为0°

(4)设置路径、生成代码工程

5、Keil5代码

(1)main函数

/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file : main.c

* @brief : Main program body

******************************************************************************

* @attention

*

* Copyright (c) 2022 STMicroelectronics.

* All rights reserved.

*

* This software is licensed under terms that can be found in the LICENSE file

* in the root directory of this software component.

* If no LICENSE file comes with this software, it is provided AS-IS.

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "main.h"

#include "tim.h"

#include "gpio.h"

/* Private includes ----------------------------------------------------------*/

/* USER CODE BEGIN Includes */

/* USER CODE END Includes */

/* Private typedef -----------------------------------------------------------*/

/* USER CODE BEGIN PTD */

/* USER CODE END PTD */

/* Private define ------------------------------------------------------------*/

/* USER CODE BEGIN PD */

/* USER CODE END PD */

/* Private macro -------------------------------------------------------------*/

/* USER CODE BEGIN PM */

/* USER CODE END PM */

/* Private variables ---------------------------------------------------------*/

/* USER CODE BEGIN PV */

/* USER CODE END PV */

/* Private function prototypes -----------------------------------------------*/

void SystemClock_Config(void);

/* USER CODE BEGIN PFP */

/* USER CODE END PFP */

/* Private user code ---------------------------------------------------------*/

/* USER CODE BEGIN 0 */

/* USER CODE END 0 */

/**

* @brief The application entry point.

* @retval int

*/

int main(void)

{

/* USER CODE BEGIN 1 */

/* USER CODE END 1 */

/* MCU Configuration--------------------------------------------------------*/

/* Reset of all peripherals, Initializes the Flash interface and the Systick. */

HAL_Init();

/* USER CODE BEGIN Init */

/* USER CODE END Init */

/* Configure the system clock */

SystemClock_Config();

/* USER CODE BEGIN SysInit */

/* USER CODE END SysInit */

/* Initialize all configured peripherals */

MX_GPIO_Init();

MX_TIM3_Init();

MX_TIM1_Init();

/* USER CODE BEGIN 2 */

HAL_TIM_PWM_Start(&htim3,TIM_CHANNEL_1);

HAL_TIM_PWM_Start(&htim3,TIM_CHANNEL_2);

HAL_TIM_PWM_Start(&htim3,TIM_CHANNEL_3);

HAL_TIM_PWM_Start(&htim3,TIM_CHANNEL_4);

/* USER CODE END 2 */

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

__HAL_TIM_SET_COMPARE(&htim3,TIM_CHANNEL_4,500);//0-180°此时对应0°

HAL_Delay(2000);

__HAL_TIM_SET_COMPARE(&htim3,TIM_CHANNEL_4,2500);//此时对应180°

HAL_Delay(2000);

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

}

/* USER CODE END 3 */

}

/**

* @brief System Clock Configuration

* @retval None

*/

void SystemClock_Config(void)

{

RCC_OscInitTypeDef RCC_OscInitStruct = {0};

RCC_ClkInitTypeDef RCC_ClkInitStruct = {0};

/** Initializes the RCC Oscillators according to the specified parameters

* in the RCC_OscInitTypeDef structure.

*/

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSE;

RCC_OscInitStruct.HSEState = RCC_HSE_ON;

RCC_OscInitStruct.HSEPredivValue = RCC_HSE_PREDIV_DIV1;

RCC_OscInitStruct.HSIState = RCC_HSI_ON;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_ON;

RCC_OscInitStruct.PLL.PLLSource = RCC_PLLSOURCE_HSE;

RCC_OscInitStruct.PLL.PLLMUL = RCC_PLL_MUL9;

if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK)

{

Error_Handler();

}

/** Initializes the CPU, AHB and APB buses clocks

*/

RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK

|RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2;

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_PLLCLK;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV2;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV1;

if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_2) != HAL_OK)

{

Error_Handler();

}

}

/* USER CODE BEGIN 4 */

/* USER CODE END 4 */

/**

* @brief This function is executed in case of error occurrence.

* @retval None

*/

void Error_Handler(void)

{

/* USER CODE BEGIN Error_Handler_Debug */

/* User can add his own implementation to report the HAL error return state */

__disable_irq();

while (1)

{

}

/* USER CODE END Error_Handler_Debug */

}

#ifdef USE_FULL_ASSERT

/**

* @brief Reports the name of the source file and the source line number

* where the assert_param error has occurred.

* @param file: pointer to the source file name

* @param line: assert_param error line source number

* @retval None

*/

void assert_failed(uint8_t *file, uint32_t line)

{

/* USER CODE BEGIN 6 */

/* User can add his own implementation to report the file name and line number,

ex: printf("Wrong parameters value: file %s on line %d\r\n", file, line) */

/* USER CODE END 6 */

}

#endif /* USE_FULL_ASSERT */

使用

HAL_TIM_PWM_Start(&htim3,TIM_CHANNEL_4);函数启动TIM的PWM输出,括号内第一个参数为启动的定时器,第二个参数为所用的通道数

使用

__HAL_TIM_SET_COMPARE(&htim3,TIM_CHANNEL_4,500);函数调整PWM的占空比,从而更改舵机角度,括号内第一个参数为启动的定时器,第二个参数为所用的通道数,第三个参数为占空比

注意:舵机使用5V供电时,C8t6同样需要5V供电,如使用3.3V供电会导致舵机转动缓慢或者不转动的现象出现!文章来源:https://www.toymoban.com/news/detail-405856.html

本例程工程文件下载:如有需要可自取用STM32CubeMX配置输出PWM信号控制多路舵机(HAL)-单片机文档类资源-CSDN下载文章来源地址https://www.toymoban.com/news/detail-405856.html

到了这里,关于用STM32CubeMX配置输出PWM信号控制多路舵机(HAL)的文章就介绍完了。如果您还想了解更多内容,请在右上角搜索TOY模板网以前的文章或继续浏览下面的相关文章,希望大家以后多多支持TOY模板网!

![12.[STM32]PWM脉宽调制-舵机控制(一篇足以)](https://imgs.yssmx.com/Uploads/2024/01/414539-1.png)