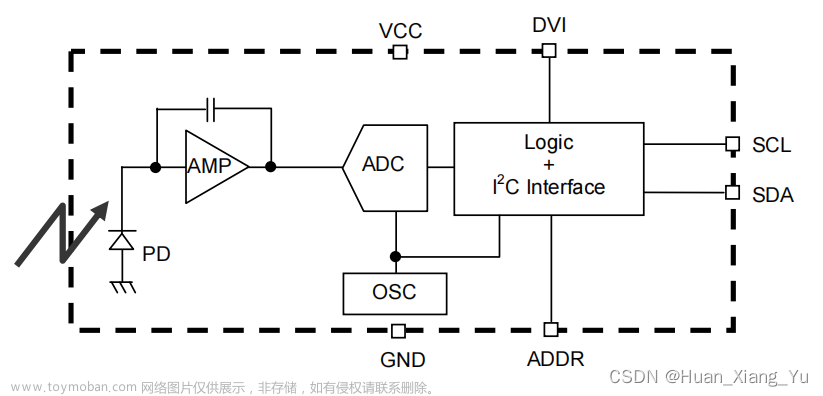

STM32F103ZET6+IIC+BH1750光照强度传感

为了加深对IIC协议的理解和应用,接下来,使用STM32驱动BH1750光照强度传感器

准备IIC协议

其实IIC协议还是之前的驱动温湿度传感的那个,只是把GPIO引脚口改了一下,同理,之后遇到使用IIC协议驱动的传感器,都可以用这个定义的IIC协议。

1、声明GPIO和IIC初始化

void BH1750_GPIO_Init(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

RCC_APB2PeriphClockCmd(BH_SCL_GPIO_CLK | BH_SDA_GPIO_SDA, ENABLE);

GPIO_InitStructure.GPIO_Pin = BH_SCL_GPIO_PIN;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_Out_PP;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(BH_SCL_GPIO_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = BH_SDA_GPIO_PIN;

GPIO_Init(BH_SDA_GPIO_PORT, &GPIO_InitStructure);

Single_Write_BH1750(0x01); //初始化BH1750

delay_ms(180);

}

2、IIC数据线的输出模式

因为在IIC数据线输出数据前,需要将数据线设置为输出模式才行

void SDA_OUT(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_InitStructure.GPIO_Pin = BH_SDA_GPIO_PIN;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_Out_PP;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(BH_SDA_GPIO_PORT, &GPIO_InitStructure);

}

3、IIC数据线的输入模式

同样在IIC数据线输入数据前,需要将数据线设置为输入模式才行

void SDA_IN(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_InitStructure.GPIO_Pin = BH_SDA_GPIO_PIN;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_10MHz;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_IN_FLOATING;

GPIO_Init(BH_SDA_GPIO_PORT, &GPIO_InitStructure);

}

4、IIC起始信号

void BH_IIC_Start(void)

{

SDA_OUT();

BH_SDA = 1;

BH_SCL = 1;

delay_us(20);

BH_SDA = 0;

delay_us(20);

BH_SCL = 0;

}

5、IIC停止信号

void BH_IIC_Stop(void)

{

SDA_OUT();

BH_SCL = 0;

BH_SDA = 0;

delay_us(20);

BH_SCL = 1;

BH_SDA = 1;

delay_us(20);

}

6、IIC等待应答信号

返回值:1,接收应答失败;0,接收应答成功。

u8 BH_IIC_Wait_Ack(void)

{

u8 ucErrTime = 0;

SDA_IN();

BH_SDA = 1;

delay_us(10);

BH_SCL = 1;

delay_us(10);

while(BH_SDA_READ())

{

ucErrTime++;

if(ucErrTime > 250)

{

BH_IIC_Stop();

return 1;

}

}

BH_SCL = 0;

return 0;

}

7、IIC产生应答信号

void BH_IIC_Ack(void)

{

BH_SCL = 0;

SDA_OUT();

BH_SDA = 0;

delay_us(20);

BH_SCL = 1;

delay_us(20);

BH_SCL = 0;

}

8、IIC不产生应答信号

void BH_IIC_NAck(void)

{

BH_SCL = 0;

SDA_OUT();

BH_SDA = 1;

delay_us(20);

BH_SCL = 1;

delay_us(20);

BH_SCL = 0;

}

9、IIC发送一个字节

返回从机有无应答,1,有应答;0,无应答。

void BH_IIC_Send_Byte(u8 txd)

{

u8 t;

SDA_OUT();

BH_SCL = 0;

for(t = 0; t < 8; t++)

{

if((txd & 0x80) >> 7)

BH_SDA = 1;

else

BH_SDA = 0;

txd <<= 1;

delay_us(20);

BH_SCL = 1;

delay_us(20);

BH_SCL = 0;

delay_us(20);

}

delay_us(20);

}

10、IIC读取一个字节

读取字节时,ask=1,产生应答;ask=0,不产生应答

u16 BH_IIC_Read_Byte(u8 ack)

{

u8 i;

u16 receive = 0;

SDA_IN();

for(i = 0; i < 8; i++ )

{

BH_SCL = 0;

delay_us(20);

BH_SCL = 1;

receive <<= 1;

if(BH_SDA_READ())

receive++;

delay_us(20);

}

if (!ack)

BH_IIC_NAck();

else

BH_IIC_Ack();

return receive;

}

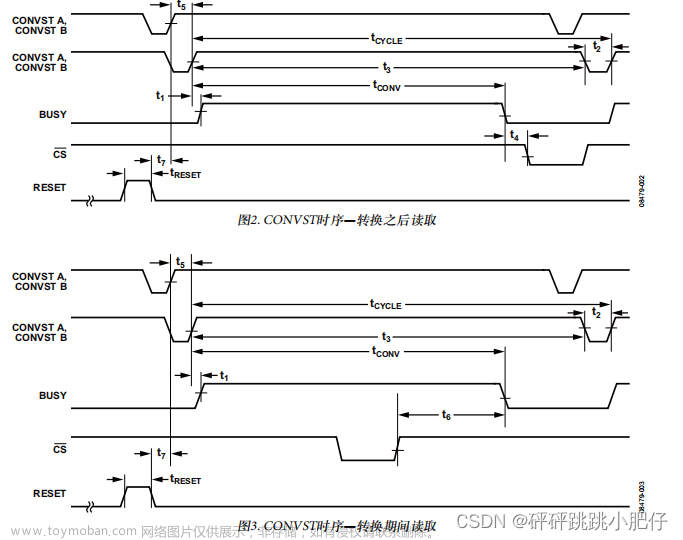

光照强度传感器的驱动过程

BH1750数据手册下载

驱动代码如下:

void Single_Write_BH1750(unsigned char REG_Address)

{

BH_IIC_Start();

BH_IIC_Send_Byte(BHAddWrite);

BH_IIC_Send_Byte(REG_Address);

BH_IIC_Stop();

}

//BH1750发送数据

void BH_Data_Send(u8 command)

{

do{

BH_IIC_Start();

BH_IIC_Send_Byte(BHAddWrite);

}while(BH_IIC_Wait_Ack());

BH_IIC_Send_Byte(command);

BH_IIC_Wait_Ack();

BH_IIC_Stop();

}

//BH1750读取数据

u16 BH_Data_Read(void)

{

u16 buf;

u8 a;

u8 b;

BH_IIC_Start();

BH_IIC_Send_Byte(BHAddRead);

BH_IIC_Wait_Ack();

b=BH_IIC_Read_Byte(1);

a=BH_IIC_Read_Byte(0);

buf=b*256+a;

BH_IIC_Stop();

return buf;

}

在之前的USART工程上,新建两个文件,一个是BH1750.h文件,另一个是BH1750.c文件

BH1750.h文件的代码如下:

#ifndef __bh1750_H

#define __bh1750_H

#include "sys.h"

#include "delay.h"

#define BH_SCL PBout(0)

#define BH_SDA PBout(1)

// GPIO 引脚定义

#define BH_SCL_GPIO_CLK RCC_APB2Periph_GPIOB

#define BH_SCL_GPIO_PORT GPIOB

#define BH_SCL_GPIO_PIN GPIO_Pin_0

#define BH_SDA_GPIO_SDA RCC_APB2Periph_GPIOB

#define BH_SDA_GPIO_PORT GPIOB

#define BH_SDA_GPIO_PIN GPIO_Pin_1

#define BH_SDA_READ() GPIO_ReadInputDataBit(BH_SDA_GPIO_PORT, BH_SDA_GPIO_PIN)

#define ADDR 0x23 //0100011

#define BHAddWrite 0x46 //从机地址+最后写方向位

#define BHAddRead 0x47 //从机地址+最后读方向位

#define BHPowDown 0x00 //关闭模块

#define BHPowOn 0x01 //打开模块等待测量指令

#define BHReset 0x07 //重置数据寄存器在poweron模式有效

#define BHModeH1 0x10 //高分辨率 单位1lx 测量时间120ms

#define BHModeH2 0x11 //高分辨率2 单位0.5lx 测量时间120ms

#define BHModeL 0x13 //低分辨率 单位4lx 测量时间16ms

#define BHSigModeH 0x20 //一次高分辨率测量后模块转到powerdown模式

#define BHSigModeH2 0x21 //同上

#define BHSigModeL 0x23 //同上

void BH1750_GPIO_Init(void);

void SDA_OUT(void);

void SDA_IN(void);

void BH_IIC_Start(void);

void BH_IIC_Stop(void);

u8 BH_IIC_Wait_Ack(void);

void BH_IIC_Ack(void);

void BH_IIC_NAck(void);

void BH_IIC_Send_Byte(u8 txd);

u16 BH_IIC_Read_Byte(u8 ack);

void Single_Write_BH1750(unsigned char REG_Address);

void BH_Data_Send(u8 command);

u16 BH_Data_Read(void);

#endif

BH1750.c文件的代码如下:

#include "BH1750.h"

void BH1750_GPIO_Init(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

RCC_APB2PeriphClockCmd(BH_SCL_GPIO_CLK | BH_SDA_GPIO_SDA, ENABLE);

GPIO_InitStructure.GPIO_Pin = BH_SCL_GPIO_PIN;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_Out_PP;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(BH_SCL_GPIO_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = BH_SDA_GPIO_PIN;

GPIO_Init(BH_SDA_GPIO_PORT, &GPIO_InitStructure);

Single_Write_BH1750(0x01);

delay_ms(180);

}

void SDA_OUT(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_InitStructure.GPIO_Pin = BH_SDA_GPIO_PIN;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_Out_PP;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(BH_SDA_GPIO_PORT, &GPIO_InitStructure);

}

void SDA_IN(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_InitStructure.GPIO_Pin = BH_SDA_GPIO_PIN;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_10MHz;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_IN_FLOATING;

GPIO_Init(BH_SDA_GPIO_PORT, &GPIO_InitStructure);

}

void BH_IIC_Start(void)

{

SDA_OUT();

BH_SDA = 1;

BH_SCL = 1;

delay_us(20);

BH_SDA = 0;

delay_us(20);

BH_SCL = 0;

}

void BH_IIC_Stop(void)

{

SDA_OUT();

BH_SCL = 0;

BH_SDA = 0;

delay_us(20);

BH_SCL = 1;

BH_SDA = 1;

delay_us(20);

}

u8 BH_IIC_Wait_Ack(void)

{

u8 ucErrTime = 0;

SDA_IN();

BH_SDA = 1;

delay_us(10);

BH_SCL = 1;

delay_us(10);

while(BH_SDA_READ())

{

ucErrTime++;

if(ucErrTime > 250)

{

BH_IIC_Stop();

return 1;

}

}

BH_SCL = 0;

return 0;

}

void BH_IIC_Ack(void)

{

BH_SCL = 0;

SDA_OUT();

BH_SDA = 0;

delay_us(20);

BH_SCL = 1;

delay_us(20);

BH_SCL = 0;

}

void BH_IIC_NAck(void)

{

BH_SCL = 0;

SDA_OUT();

BH_SDA = 1;

delay_us(20);

BH_SCL = 1;

delay_us(20);

BH_SCL = 0;

}

void BH_IIC_Send_Byte(u8 txd)

{

u8 t;

SDA_OUT();

BH_SCL = 0;

for(t = 0; t < 8; t++)

{

if((txd & 0x80) >> 7)

BH_SDA = 1;

else

BH_SDA = 0;

txd <<= 1;

delay_us(20);

BH_SCL = 1;

delay_us(20);

BH_SCL = 0;

delay_us(20);

}

delay_us(20);

}

u16 BH_IIC_Read_Byte(u8 ack)

{

u8 i;

u16 receive = 0;

SDA_IN();

for(i = 0; i < 8; i++ )

{

BH_SCL = 0;

delay_us(20);

BH_SCL = 1;

receive <<= 1;

if(BH_SDA_READ())

receive++;

delay_us(20);

}

if (!ack)

BH_IIC_NAck();

else

BH_IIC_Ack();

return receive;

}

void Single_Write_BH1750(unsigned char REG_Address)

{

BH_IIC_Start();

BH_IIC_Send_Byte(BHAddWrite);

BH_IIC_Send_Byte(REG_Address);

BH_IIC_Stop();

}

void BH_Data_Send(u8 command)

{

do{

BH_IIC_Start();

BH_IIC_Send_Byte(BHAddWrite);

}while(BH_IIC_Wait_Ack());

BH_IIC_Send_Byte(command);

BH_IIC_Wait_Ack();

BH_IIC_Stop();

}

u16 BH_Data_Read(void)

{

u16 buf;

u8 a;

u8 b;

BH_IIC_Start();

BH_IIC_Send_Byte(BHAddRead);

BH_IIC_Wait_Ack();

b=BH_IIC_Read_Byte(1);

a=BH_IIC_Read_Byte(0);

buf=b*256+a;

BH_IIC_Stop();

return buf;

}

main.c文件的代码如下:

#include "stm32f10x.h"

#include <stdio.h>

#include "led.h"

#include "USART_Init_Config.h"

#include "BH1750.h"

int main(void)

{

int x=0;

float c;

delay_init(); //延时函数初始化

LED_Init(); //LED灯初始化

USART_Init_Config(); //串口初始化

BH1750_GPIO_Init(); //初始化BH1750

BH_Data_Send(BHPowOn);

delay_ms(2000);

while(1)

{

BH_Data_Send(BHReset);

BH_Data_Send(BHModeH1);

delay_ms(180);

x=BH_Data_Read();

c=x/1.2;

printf("光照强度为:%0.2f",c);

delay_ms(1000);

}

}

运行效果

打开串口调试助手文章来源:https://www.toymoban.com/news/detail-410149.html

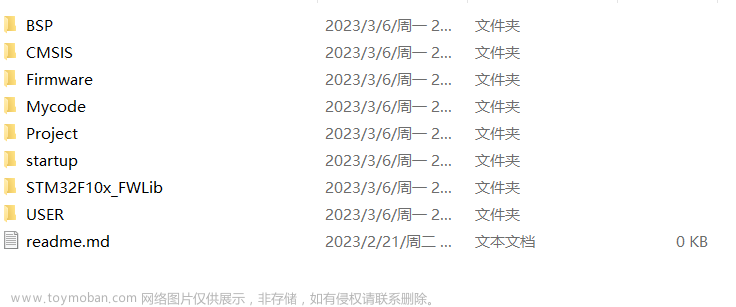

完整工程下载!!!文章来源地址https://www.toymoban.com/news/detail-410149.html

到了这里,关于STM32F103ZET6+IIC+BH1750光照强度传感的文章就介绍完了。如果您还想了解更多内容,请在右上角搜索TOY模板网以前的文章或继续浏览下面的相关文章,希望大家以后多多支持TOY模板网!