STM32模拟SPI协议获取24位模数转换(24bit ADC)芯片AD7791电压采样数据

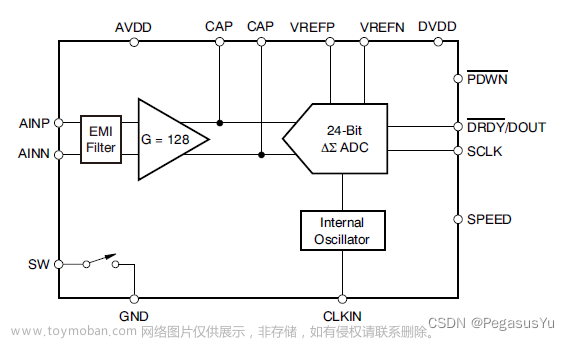

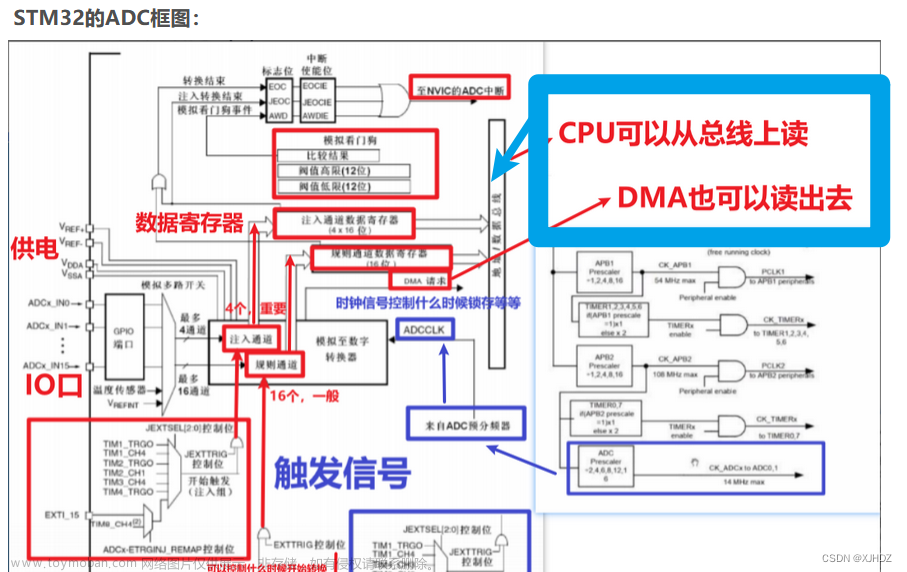

STM32大部分芯片只有12位的ADC采样性能,如果要实现更高精度的模数转换如24位ADC采样,则需要连接外部ADC实现。AD7791是亚德诺(ADI)半导体一款用于低功耗、24位Σ-Δ型模数转换器(ADC) ,适合低频测量应用,提供50 Hz/60 Hz同步抑制。

这里介绍基于AD7791的24位ADC采样实现。

AD7791控制协议

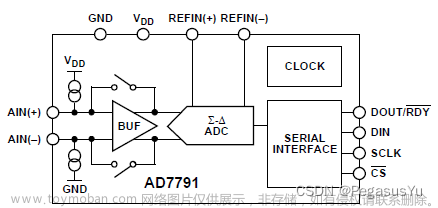

AD7791的管脚如下所示:

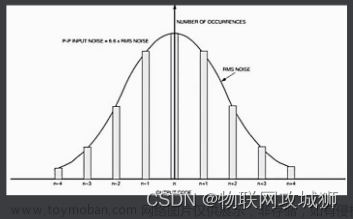

AD7791可以工作在2.5V~5.25V供电范围(VDD),而用于模数转换的参考电压可以通过引脚REFIN(+)和REFIN(–)单独设置,从而可以针对特定电压范围更高精度的采样。如果REFIN(+) - REFIN(–) = 1V, 则对应24位采样分辨率率为1/(2^24)=0.00000006V。当然要使得这个级别的电压分辨率有效,对电路噪声的控制要求也很高。

AIN(+)和AIN(-)用于连接输入信号,通过芯片内部寄存器配置,有两种转换模式,即AIN(+)相对AIN(-)是单边电压或双边电压。单边电压模式,采样值0x000000对应AIN(+)-AIN(-)=0,采样值0xFFFFFF对应AIN(+)-AIN(-)=REFIN(+) - REFIN(–) 。双边电压模式,采样值0x000000对应AIN(+)-AIN(-)=-(REFIN(+) - REFIN(–)),采样值0x800000对应AIN(+)-AIN(-)=0,采样值0xFFFFFF对应AIN(+)-AIN(-)=REFIN(+) - REFIN(–) 。

AD7791通过SPI总线进行访问控制,其中数据输出管脚DOUT也是转换完成可读取指示信号/RDY, 访问协议操作主要逻辑如下:

- 向通讯寄存器发送指令,设置采样的通道和读操作模式(单次或连续),并且设置下一次访问是对哪个寄存器进行操作,以及进行的是读还是写;

- 写模式寄存器,设置采用单次转换还是连续转换模式,单边还是双边转换模式,以及是否buffered模式(buffered模式对应信号接收管脚端接收阻抗高阻模式),以及buffered模式是否在输入端引用100ns电流源;

- 在配置模式寄存器后,可以再向通讯寄存器发送指令指示后续读取数据寄存器,然后按照24位格式读取采样到的ADC值;

- 芯片支持对供电电压的采样识别,原理为供电电压内部LDO降压到1.17V作为VDD采样电路的参考供电,而VDD本身分压到1/5接到ADC采样端。所以供电电压识别为( VDD采样值 / 16777216 ) * 1.17 * 5 V.

- 可配置滤波寄存器以控制采样转换输出频率,影响到噪声抑制级别;

- 可以读取状态寄存器获得一些状态信息。

STM32工程配置

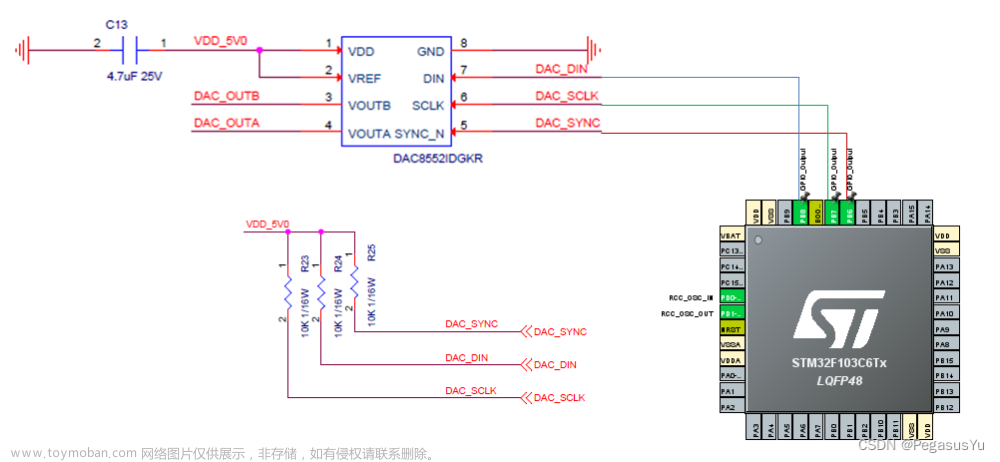

这里以STM32F103C6T6及STM32CUBEIDE开发工具为例,介绍AD7791的24位ADC采样实现。

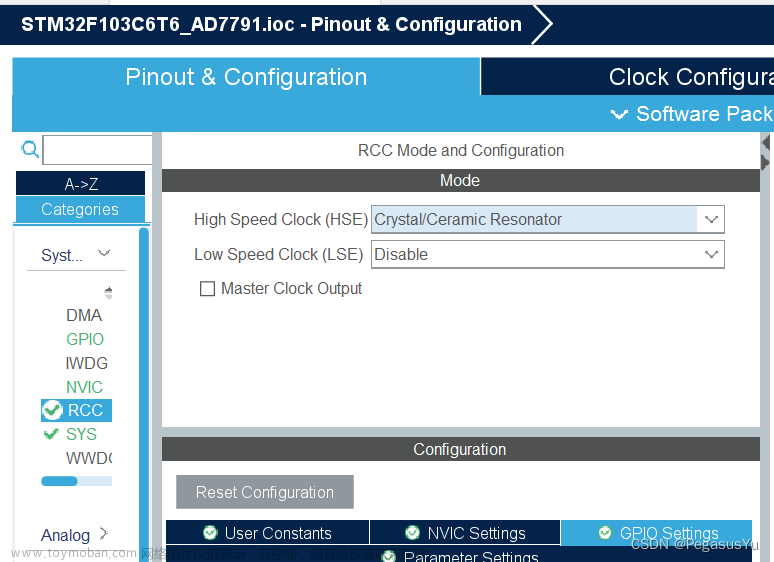

首先建立基本工程并配置时钟:

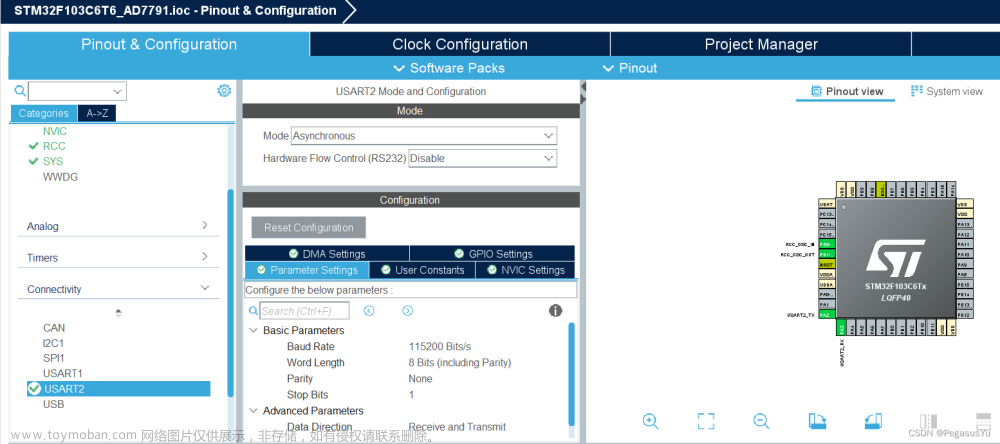

配置一个串口如UART2作为通讯打印输出口

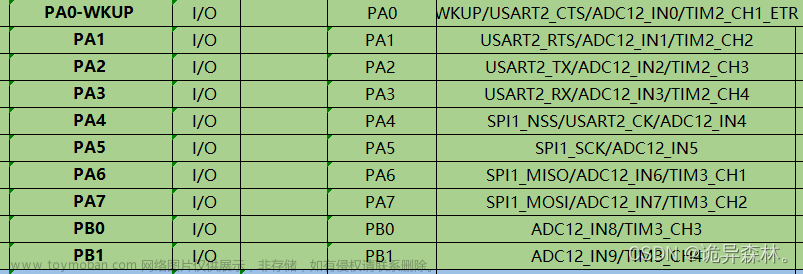

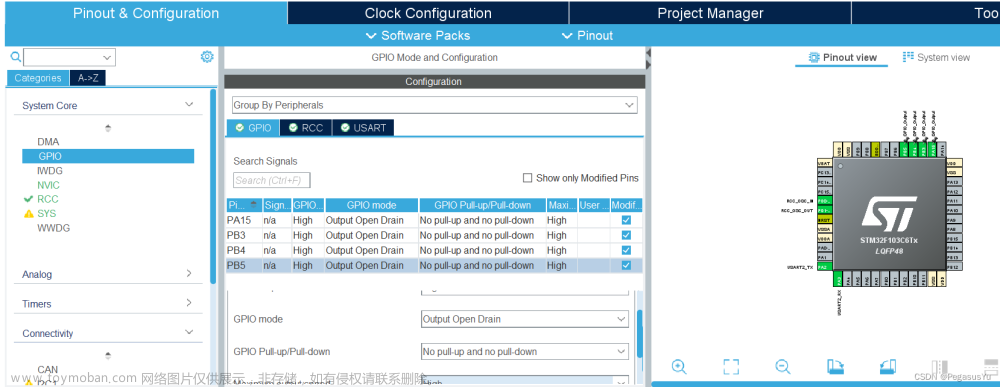

再选择4根管脚作为模拟协议用的GPIO, 这里用PA15作为CS,PB3作为CLK,PB4作为MISO, PB5作为MOSI,各管脚上外部电阻上拉到AD7791的供电电压,STM32的管脚配置为Open-drain模式,从而可以兼容不同供电电压的AD7791访问连接, 因此STM32的GPIO也都选择为具有FT(5V耐压)能力的管脚。

保存并生成基本工程代码:

STM32工程代码

AD7791的ADC数据读取有5种模式:

- 单次转换单次单读

- 单次转换多次单读(读到同样的数据)

- 连续转换单次单读

- 连续转换多次单读

- 连续抓换多次连读

其中单读和连续的区别是,单读的每次读取前要发送一次写操作,连续的所有读取前只发送一次写操作。这里的工程代码对5种模式都做了函数实现。

代码采用的微秒级延时函数实现,参考: STM32 HAL us delay(微秒延时)的指令延时实现方式及优化

代码用到串口打印printf函数的重载及采用的浮点转换函数,参考: STM32 UART串口printf函数应用及浮点打印代码空间节省 (HAL)

完整的main.c工程代码如下:

/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file : main.c

* @brief : Main program body

******************************************************************************

* @attention

*

* Copyright (c) 2022 STMicroelectronics.

* All rights reserved.

*

* This software is licensed under terms that can be found in the LICENSE file

* in the root directory of this software component.

* If no LICENSE file comes with this software, it is provided AS-IS.

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "main.h"

/* Private includes ----------------------------------------------------------*/

/* USER CODE BEGIN Includes */

#include "usart.h"

/* USER CODE END Includes */

/* Private typedef -----------------------------------------------------------*/

/* USER CODE BEGIN PTD */

/* USER CODE END PTD */

/* Private define ------------------------------------------------------------*/

/* USER CODE BEGIN PD */

__IO float usDelayBase;

void PY_usDelayTest(void)

{

__IO uint32_t firstms, secondms;

__IO uint32_t counter = 0;

firstms = HAL_GetTick()+1;

secondms = firstms+1;

while(uwTick!=firstms) ;

while(uwTick!=secondms) counter++;

usDelayBase = ((float)counter)/1000;

}

void PY_Delay_us_t(uint32_t Delay)

{

__IO uint32_t delayReg;

__IO uint32_t usNum = (uint32_t)(Delay*usDelayBase);

delayReg = 0;

while(delayReg!=usNum) delayReg++;

}

void PY_usDelayOptimize(void)

{

__IO uint32_t firstms, secondms;

__IO float coe = 1.0;

firstms = HAL_GetTick();

PY_Delay_us_t(1000000) ;

secondms = HAL_GetTick();

coe = ((float)1000)/(secondms-firstms);

usDelayBase = coe*usDelayBase;

}

void PY_Delay_us(uint32_t Delay)

{

__IO uint32_t delayReg;

__IO uint32_t msNum = Delay/1000;

__IO uint32_t usNum = (uint32_t)((Delay%1000)*usDelayBase);

if(msNum>0) HAL_Delay(msNum);

delayReg = 0;

while(delayReg!=usNum) delayReg++;

}

/*

*Convert float to string type

*Written by Pegasus Yu in 2022

*stra: string address as mychar from char mychar[];

*float: float input like 12.345

*flen: fraction length as 3 for 12.345

*/

#include <stdio.h>

#include <string.h>

#include <stdlib.h>

#include <math.h>

void py_f2s4printf(char * stra, float x, uint8_t flen)

{

uint32_t base;

int64_t dn;

char mc[32];

base = pow(10,flen);

dn = x*base;

sprintf(stra, "%d.", (int)(dn/base));

dn = abs(dn);

if(dn%base==0)

{

for(uint8_t j=1;j<=flen;j++)

{

stra = strcat(stra, "0");

}

return;

}

else

{

if(flen==1){

sprintf(mc, "%d", (int)(dn%base));

stra = strcat(stra, mc);

return;

}

for(uint8_t j=1;j<flen;j++)

{

if((dn%base)<pow(10,j))

{

for(uint8_t k=1;k<=(flen-j);k++)

{

stra = strcat(stra, "0");

}

sprintf(mc, "%d", (int)(dn%base));

stra = strcat(stra, mc);

return;

}

}

sprintf(mc, "%d", (int)(dn%base));

stra = strcat(stra, mc);

return;

}

}

/* USER CODE END PD */

/* Private macro -------------------------------------------------------------*/

/* USER CODE BEGIN PM */

#define AD7791_CS_LOW HAL_GPIO_WritePin(GPIOA, GPIO_PIN_15, GPIO_PIN_RESET)

#define AD7791_CS_HIGH HAL_GPIO_WritePin(GPIOA, GPIO_PIN_15, GPIO_PIN_SET)

#define AD7791_CLK_LOW HAL_GPIO_WritePin(GPIOB, GPIO_PIN_3, GPIO_PIN_RESET)

#define AD7791_CLK_HIGH HAL_GPIO_WritePin(GPIOB, GPIO_PIN_3, GPIO_PIN_SET)

#define AD7791_DIN_LOW HAL_GPIO_WritePin(GPIOB, GPIO_PIN_5, GPIO_PIN_RESET)

#define AD7791_DIN_HIGH HAL_GPIO_WritePin(GPIOB, GPIO_PIN_5, GPIO_PIN_SET)

#define AD7791_DOUT_nRDY HAL_GPIO_ReadPin(GPIOB, GPIO_PIN_4)

void AD7791_RST(void)

{

/*

* The serial interface can be reset by writing a series of 1s on the DIN input. If a Logic 1 is written to the AD7791 line for at least

* 32 serial clock cycles, the serial interface is reset.

*

* The DOUT/ RDY pin operates as a Data Ready signal also, the line going low when a new data-word is available in the output register.

* It is reset high when a read operation from the data register is complete.

* It also goes high prior to the updating of the data register to indicate when not to read from the device to ensure that a data read is

* not attempted while the register is being updated.

*/

AD7791_CS_HIGH;

AD7791_DIN_HIGH;

AD7791_CLK_HIGH;

AD7791_CS_LOW;

PY_Delay_us_t(1);

for(uint8_t i=0;i<32;i++)

{

AD7791_CLK_LOW;

PY_Delay_us_t(1);

AD7791_CLK_HIGH;

PY_Delay_us_t(1);

}

AD7791_DIN_LOW;

AD7791_CS_HIGH;

}

/*

* write access to any of the other registers on the part begins with a write operation to the communications register followed by a

* write to the selected register.

* A read operation from any other register (except when continuous read mode is selected) starts

* with a write to the communications register followed by a read operation from the selected register.

*/

void AD7791_WR_1BYTE(uint8_t cmd) //write 8-bit data

{

for(uint8_t i=0; i<8; i++)

{

AD7791_CLK_LOW;

if ((cmd<<i)&0x80) AD7791_DIN_HIGH;

else AD7791_DIN_LOW;

PY_Delay_us_t(1);

AD7791_CLK_HIGH;

PY_Delay_us_t(1);

}

}

uint32_t AD7791_RD_3BYTE(void) //read 24-bit data

{

uint8_t rbit = 0;

uint32_t rdata = 0;

for(uint8_t i=1; i<=24; i++)

{

PY_Delay_us_t(1);

AD7791_CLK_LOW;

PY_Delay_us_t(1);

AD7791_CLK_HIGH;

rbit = AD7791_DOUT_nRDY;

if (rbit != 0) rdata |= (((uint32_t)rbit)<<(24-i));

}

return rdata;

}

void AD7791_POWER_DOWN(void)

{

AD7791_CLK_HIGH;

AD7791_CS_LOW;

AD7791_WR_1BYTE(0x10);

AD7791_WR_1BYTE(0xc4);

AD7791_CS_HIGH;

}

uint8_t AD7791_READ_STATUS_REG(void)

{

uint8_t rbit = 0;

uint8_t rdata = 0;

AD7791_CLK_HIGH;

AD7791_CS_LOW;

AD7791_WR_1BYTE(0x08);

AD7791_DIN_LOW;

AD7791_CLK_HIGH;

for(uint8_t i=1; i<=8; i++)

{

PY_Delay_us_t(1);

AD7791_CLK_LOW;

PY_Delay_us_t(1);

AD7791_CLK_HIGH;

rbit = AD7791_DOUT_nRDY;

if (rbit != 0) rdata |= ((rbit)<<(8-i));

}

AD7791_CS_HIGH;

return rdata;

}

uint8_t AD7791_SET_FILTER_REG(uint8_t data)

{

/*

* Due to chip fault, 0 or 1 written to lowest bit of filter register will become 1. So to write 0x04 will get back-read value 0x05.

* So don't write filter register if you want to keep 0x04 in filter register which will be filled 0x04 when power up.

*/

uint8_t mode = 0x04; //default: clock without division, 16.6Hz output rate

uint8_t rbit = 0;

uint8_t rdata = 0;

AD7791_CLK_HIGH;

AD7791_CS_LOW;

AD7791_WR_1BYTE(0x20);

mode = data;

AD7791_WR_1BYTE(mode);

AD7791_CS_HIGH;

AD7791_RST();

PY_Delay_us_t(1);

AD7791_CLK_HIGH;

AD7791_CS_LOW;

AD7791_WR_1BYTE(0x28);

AD7791_DIN_LOW;

AD7791_CLK_HIGH;

for(uint8_t i=1; i<=8; i++)

{

PY_Delay_us_t(1);

AD7791_CLK_LOW;

PY_Delay_us_t(1);

AD7791_CLK_HIGH;

rbit = AD7791_DOUT_nRDY;

if (rbit != 0) rdata |= ((rbit)<<(8-i));

}

AD7791_CS_HIGH;

return rdata;

}

uint32_t AD7791_SAMPLE_VDD_SINGLE(void)

{

/*

* Along with converting external voltages, the analog input chan-nel can be used to monitor the voltage on the VDD pin.

* When the CH1 and CH0 bits in the communications register are set to 1,

* the voltage on the VDD pin is internally attenuated by 5 and the resultant voltage is applied to the Σ-Δ modulator using an internal 1.17 V reference for analog to digital conversion.

*/

uint32_t vdd = 0;

AD7791_CLK_HIGH;

AD7791_CS_LOW;

AD7791_WR_1BYTE(0x17);

AD7791_WR_1BYTE(0x06);

while(AD7791_DOUT_nRDY) ;

AD7791_WR_1BYTE(0x3f);

vdd = AD7791_RD_3BYTE();

AD7791_CS_HIGH;

AD7791_RST();

return vdd;

/*

* voltage = (vdd/16777216)*1.17*5

*/

}

/* *

* Mode1: single conversion mode + single read mode : get one-time 24-bit data (write operation advanced before read operation)

* Mode2: single conversion mode + multi-time single read mode: get multi-time same 24-bit data (write operation advanced before every read operation)

* Mode3: continuous conversion mode + single read mode: get one-time 24-bit data (write operation advanced before read operation)

* Mode4: continuous conversion mode + multi-time single read mode: get multi-time individual 24-bit data (write operation advanced before every read operation)

* Mode5: continuous conversion mode + continuous read mode: get multi-time individual 24-bit data (only once write operation for all read operations)

*/

void AD7791_Mode1_RD(uint32_t *result)

{

AD7791_CLK_HIGH;

AD7791_CS_LOW;

//AD7791_WR_1BYTE(0x12); //used for AIN(–) – AIN(–) test only

AD7791_WR_1BYTE(0x10);

AD7791_WR_1BYTE(0x86);//single conversion mode, no burn-out current, uni-polar and buffered

while(AD7791_DOUT_nRDY) ;

AD7791_WR_1BYTE(0x38);//single read

(*result) = AD7791_RD_3BYTE();

AD7791_CS_HIGH;

AD7791_RST();

}

void AD7791_Mode2_RD(uint32_t *result, uint32_t times)

{

AD7791_CLK_HIGH;

AD7791_CS_LOW;

AD7791_WR_1BYTE(0x10);

AD7791_WR_1BYTE(0x86);//single conversion mode, no burn-out current, uni-polar and buffered

while(AD7791_DOUT_nRDY) ;

for(uint32_t i=0; i<times; i++)

{

AD7791_WR_1BYTE(0x38);//single read

result[i] = AD7791_RD_3BYTE();

PY_Delay_us_t(1);

}

AD7791_CS_HIGH;

AD7791_RST();

}

void AD7791_Mode3_RD(uint32_t *result)

{

AD7791_CLK_HIGH;

AD7791_CS_LOW;

AD7791_WR_1BYTE(0x10);

AD7791_WR_1BYTE(0x06);//continuous conversion mode, no burn-out current, uni-polar and buffered

while(AD7791_DOUT_nRDY) ;

AD7791_WR_1BYTE(0x38);//single read

(*result) = AD7791_RD_3BYTE();

AD7791_CS_HIGH;

AD7791_RST();

}

void AD7791_Mode4_RD(uint32_t *result, uint32_t times)

{

AD7791_CLK_HIGH;

AD7791_CS_LOW;

AD7791_WR_1BYTE(0x10);

AD7791_WR_1BYTE(0x06);//continuous conversion mode, no burn-out current, uni-polar and buffered

for(uint32_t i=0; i<times; i++)

{

while(AD7791_DOUT_nRDY) ;

AD7791_WR_1BYTE(0x38);//single read

result[i] = AD7791_RD_3BYTE();

PY_Delay_us_t(1);

}

AD7791_CS_HIGH;

AD7791_RST();

}

void AD7791_Mode5_RD(uint32_t *result, uint32_t times)

{

AD7791_CLK_HIGH;

AD7791_CS_LOW;

AD7791_WR_1BYTE(0x10);

AD7791_WR_1BYTE(0x06);//continuous conversion mode, no burn-out current, uni-polar and buffered

AD7791_WR_1BYTE(0x3c);//continuous read

for(uint32_t i=0; i<times; i++)

{

while(AD7791_DOUT_nRDY) ;

result[i] = AD7791_RD_3BYTE();

PY_Delay_us_t(1);

}

AD7791_CS_HIGH;

AD7791_RST();

}

/* USER CODE END PM */

/* Private variables ---------------------------------------------------------*/

UART_HandleTypeDef huart2;

/* USER CODE BEGIN PV */

/* USER CODE END PV */

/* Private function prototypes -----------------------------------------------*/

void SystemClock_Config(void);

static void MX_GPIO_Init(void);

static void MX_USART2_UART_Init(void);

/* USER CODE BEGIN PFP */

/* USER CODE END PFP */

/* Private user code ---------------------------------------------------------*/

/* USER CODE BEGIN 0 */

/* USER CODE END 0 */

/**

* @brief The application entry point.

* @retval int

*/

int main(void)

{

/* USER CODE BEGIN 1 */

uint32_t AData[128];

float vdd;

char mychar[100];

/* USER CODE END 1 */

/* MCU Configuration--------------------------------------------------------*/

/* Reset of all peripherals, Initializes the Flash interface and the Systick. */

HAL_Init();

/* USER CODE BEGIN Init */

/* USER CODE END Init */

/* Configure the system clock */

SystemClock_Config();

/* USER CODE BEGIN SysInit */

/* USER CODE END SysInit */

/* Initialize all configured peripherals */

MX_GPIO_Init();

MX_USART2_UART_Init();

/* USER CODE BEGIN 2 */

PY_usDelayTest();

PY_usDelayOptimize();

/* USER CODE END 2 */

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

printf("Status Register Read Value=0x%02x\r\n", AD7791_READ_STATUS_REG());

printf("Filter Register Set Value=0x%02x\r\n", AD7791_SET_FILTER_REG(0x05));

vdd = ((float)AD7791_SAMPLE_VDD_SINGLE())*1.17*5/16777216;

py_f2s4printf(mychar, vdd, 6);

printf("VDD Sampling Read Value=%s V\r\n", mychar);

AD7791_Mode1_RD(AData);

printf("Mode 1 Signal Sampling Read Value=%d\r\n", AData[0]);

AD7791_Mode2_RD(AData, 4);

printf("Mode 2 Signal Sampling Read Value:\r\n%d\r\n%d\r\n%d\r\n%d\r\n", AData[0], AData[1], AData[2], AData[3]);

AD7791_Mode3_RD(AData);

printf("Mode 3 Signal Sampling Read Value=%d\r\n", AData[0]);

AD7791_Mode4_RD(AData, 4);

printf("Mode 4 Signal Sampling Read Value:\r\n%d\r\n%d\r\n%d\r\n%d\r\n", AData[0], AData[1], AData[2], AData[3]);

AD7791_Mode5_RD(AData, 4);

printf("Mode 5 Signal Sampling Read Value:\r\n%d\r\n%d\r\n%d\r\n%d\r\n", AData[0], AData[1], AData[2], AData[3]);

PY_Delay_us_t(1000000);

printf("\r\n");

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

}

/* USER CODE END 3 */

}

/**

* @brief System Clock Configuration

* @retval None

*/

void SystemClock_Config(void)

{

RCC_OscInitTypeDef RCC_OscInitStruct = {0};

RCC_ClkInitTypeDef RCC_ClkInitStruct = {0};

/** Initializes the RCC Oscillators according to the specified parameters

* in the RCC_OscInitTypeDef structure.

*/

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSE;

RCC_OscInitStruct.HSEState = RCC_HSE_ON;

RCC_OscInitStruct.HSEPredivValue = RCC_HSE_PREDIV_DIV1;

RCC_OscInitStruct.HSIState = RCC_HSI_ON;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_ON;

RCC_OscInitStruct.PLL.PLLSource = RCC_PLLSOURCE_HSE;

RCC_OscInitStruct.PLL.PLLMUL = RCC_PLL_MUL9;

if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK)

{

Error_Handler();

}

/** Initializes the CPU, AHB and APB buses clocks

*/

RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK

|RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2;

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_PLLCLK;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV2;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV1;

if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_2) != HAL_OK)

{

Error_Handler();

}

}

/**

* @brief USART2 Initialization Function

* @param None

* @retval None

*/

static void MX_USART2_UART_Init(void)

{

/* USER CODE BEGIN USART2_Init 0 */

/* USER CODE END USART2_Init 0 */

/* USER CODE BEGIN USART2_Init 1 */

/* USER CODE END USART2_Init 1 */

huart2.Instance = USART2;

huart2.Init.BaudRate = 115200;

huart2.Init.WordLength = UART_WORDLENGTH_8B;

huart2.Init.StopBits = UART_STOPBITS_1;

huart2.Init.Parity = UART_PARITY_NONE;

huart2.Init.Mode = UART_MODE_TX_RX;

huart2.Init.HwFlowCtl = UART_HWCONTROL_NONE;

huart2.Init.OverSampling = UART_OVERSAMPLING_16;

if (HAL_UART_Init(&huart2) != HAL_OK)

{

Error_Handler();

}

/* USER CODE BEGIN USART2_Init 2 */

/* USER CODE END USART2_Init 2 */

}

/**

* @brief GPIO Initialization Function

* @param None

* @retval None

*/

static void MX_GPIO_Init(void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

/* GPIO Ports Clock Enable */

__HAL_RCC_GPIOD_CLK_ENABLE();

__HAL_RCC_GPIOA_CLK_ENABLE();

__HAL_RCC_GPIOB_CLK_ENABLE();

/*Configure GPIO pin Output Level */

HAL_GPIO_WritePin(GPIOA, GPIO_PIN_15, GPIO_PIN_SET);

/*Configure GPIO pin Output Level */

HAL_GPIO_WritePin(GPIOB, GPIO_PIN_3|GPIO_PIN_4|GPIO_PIN_5, GPIO_PIN_SET);

/*Configure GPIO pin : PA15 */

GPIO_InitStruct.Pin = GPIO_PIN_15;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_OD;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(GPIOA, &GPIO_InitStruct);

/*Configure GPIO pins : PB3 PB4 PB5 */

GPIO_InitStruct.Pin = GPIO_PIN_3|GPIO_PIN_4|GPIO_PIN_5;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_OD;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(GPIOB, &GPIO_InitStruct);

}

/* USER CODE BEGIN 4 */

/* USER CODE END 4 */

/**

* @brief This function is executed in case of error occurrence.

* @retval None

*/

void Error_Handler(void)

{

/* USER CODE BEGIN Error_Handler_Debug */

/* User can add his own implementation to report the HAL error return state */

__disable_irq();

while (1)

{

}

/* USER CODE END Error_Handler_Debug */

}

#ifdef USE_FULL_ASSERT

/**

* @brief Reports the name of the source file and the source line number

* where the assert_param error has occurred.

* @param file: pointer to the source file name

* @param line: assert_param error line source number

* @retval None

*/

void assert_failed(uint8_t *file, uint32_t line)

{

/* USER CODE BEGIN 6 */

/* User can add his own implementation to report the file name and line number,

ex: printf("Wrong parameters value: file %s on line %d\r\n", file, line) */

/* USER CODE END 6 */

}

#endif /* USE_FULL_ASSERT */

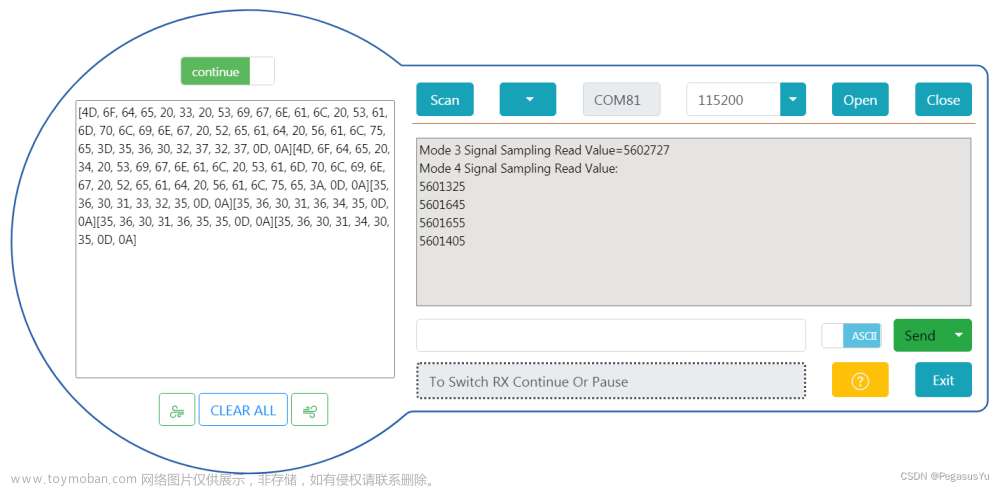

STM32测试输出

串口测试输出如下:

例程下载

STM32F103C6T6模拟SPI协议读取24位模数转换(24bit ADC)芯片AD7791数据例程文章来源:https://www.toymoban.com/news/detail-485300.html

–End–文章来源地址https://www.toymoban.com/news/detail-485300.html

到了这里,关于STM32模拟SPI协议获取24位模数转换(24bit ADC)芯片AD7791电压采样数据的文章就介绍完了。如果您还想了解更多内容,请在右上角搜索TOY模板网以前的文章或继续浏览下面的相关文章,希望大家以后多多支持TOY模板网!