一、知识点补充

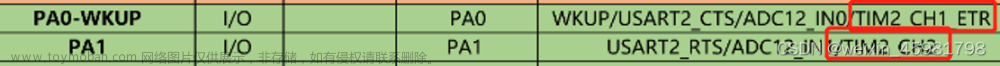

1.PWM波输出与GPIO的引脚对应关系图

a. TIM2的引脚复用子啊PA0引脚上,所以TIM2、CH1、PA0三者是捆绑在一起的,即在PA0引脚上通过TIM2通道1CH1输出PWM

b. TIM2、CH1、PA0三者一般是捆绑在一起,但可以通过重映射改变

c. TIM2、CH2、PA1同理

2.重映射简介

改为PA15,选择重映射方式1或完全重映射

在时钟开启后写入

RCC_APB2PeriphClockCmd(RCC_APB2Periph_AFIO, ENABLE);

GPIO_PinRemapConfig(GPIO_PartialRemap1_TIM2, ENABLE);

GPIO_PinRemapConfig(GPIO_Remap_SWJ_JTAGDisable, ENABLE); //PA15为调试端口,需要解除调试端

若想要让PA15、PB3、PB4这三个引脚当作普通GPIO来使用,则加第一、三句,打开AFIO时钟,让AFIO时钟将JTAG复用解除掉

如果想要重映射定时器或者其他外设的复用引脚,加第一句和第二句,就要先打开AFIO时钟,再用AFIO重映射外设复用的引脚,

若重映射的引脚正好是调试端口,则三句全加上

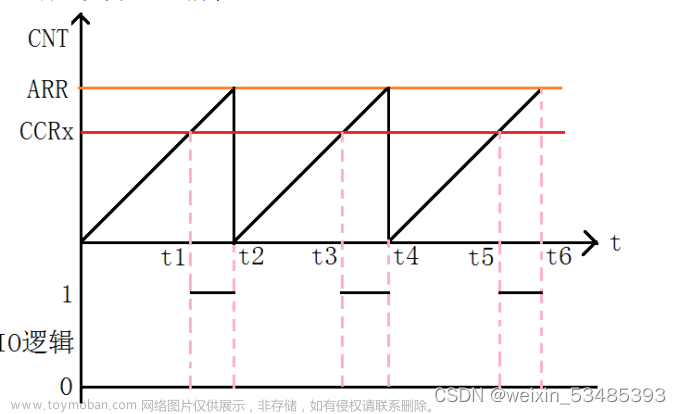

3.计数器的计算

PWM频率=计数器更新频率

比如要产生一个频率为1KHz,占空比为50%,分辨率为1%的PWM波形

72M/(PSC+1)/ (ARR+1)=1000

CCR/(ARR+1)=0.5

1/(ARR+1)=0.01

计算得:ARR=99,CCR=50, PSC=720-1;

4.基本步骤

第一步:RCC开启时钟,打开TIM外设和GPIO外设的时钟

第二步:配置时基单元,包括时基单元和时基单元前的时钟源选择(不选择则默认内部时钟)

第三步:配置输出比较单元,里面包括CCR的值、输出比较模式、极性选择、输出使能(结构体配置)

第四步:配置GPIO口,初始化为复用推挽输出的配置

第五步:运行控制,启动计数器,就能输出PWM波

5.输出比较模式简介

常用模式为 PWM1模式1

二、实例

1.PWM驱动LED灯

PWM.c

#include "stm32f10x.h" // Device header

void PWM_Init(void)

{

RCC_APB1PeriphClockCmd(RCC_APB1Periph_TIM2, ENABLE); //第一步,开启时钟

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA, ENABLE);

// RCC_APB2PeriphClockCmd(RCC_APB2Periph_AFIO, ENABLE);

// GPIO_PinRemapConfig(GPIO_PartialRemap1_TIM2, ENABLE);

// GPIO_PinRemapConfig(GPIO_Remap_SWJ_JTAGDisable, ENABLE);

GPIO_InitTypeDef GPIO_InitStructure; //第四步,配置GPIO

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_PP;

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_0; //GPIO_Pin_15;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(GPIOA, &GPIO_InitStructure);

TIM_TimeBaseInitTypeDef TIM_TimeBaseInitStructure; //第二步,配置时基单元

TIM_TimeBaseInitStructure.TIM_ClockDivision = TIM_CKD_DIV1;

TIM_TimeBaseInitStructure.TIM_CounterMode = TIM_CounterMode_Up;

TIM_TimeBaseInitStructure.TIM_Period = 100 - 1; //ARR

TIM_TimeBaseInitStructure.TIM_Prescaler = 720 - 1; //PSC

TIM_TimeBaseInitStructure.TIM_RepetitionCounter = 0;

TIM_TimeBaseInit(TIM2, &TIM_TimeBaseInitStructure);

TIM_OCInitTypeDef TIM_OCInitStructure; //第三步,配置输出比较单元(CCR)

TIM_OCStructInit(&TIM_OCInitStructure); //初始化所以结构体(结构体中有带N的变量,是高级配置输出比较单元才有的,本次实例不需要用到,初始化后让他不影响别的模块)

TIM_OCInitStructure.TIM_OCMode = TIM_OCMode_PWM1; //设置比较输出模式

TIM_OCInitStructure.TIM_OCPolarity = TIM_OCPolarity_High; //设置极性

TIM_OCInitStructure.TIM_OutputState = TIM_OutputState_Enable; //设置输出使能

TIM_OCInitStructure.TIM_Pulse = 0; //CCR(0-0xff)

TIM_OC1Init(TIM2, &TIM_OCInitStructure);

TIM_Cmd(TIM2,ENABLE);//第五步,运行控制启动

}

void PWM_SetCompare1(uint16_t Compare) //由main.c设置占空比

{

TIM_SetCompare1(TIM2,Compare);

}

PWM.h

#ifndef __PWM_H__

#define __PWM_H__

void PWM_SetCompare1(uint16_t Compare);

void PWM_Init(void);

#endif

main.c

#include "stm32f10x.h" // Device header

#include "Delay.h"

#include "OLED.h"

#include "PWM.h"

uint8_t i;

int main(void)

{

OLED_Init();

PWM_Init();

while(1)

{

for(i=0;i<=100;i++) 更改CCR值

{

PWM_SetCompare1(i);

Delay_ms(10);

}

for(i=0;i<=100;i++)

{

PWM_SetCompare1(100-i);

Delay_ms(10);

}

}

}

2.PWM驱动舵机

参数计算

舵机要求频率 :50Hz(周期为20ms)

舵机角度控制(占空比):0.5-2.5ms(时长)

(3个变量,2个方程)解不是唯一的

为方便计算

取PSC+1=72,ARR+1=20k

当CCR=500时,高电平时长为0.5ms

PWM.c

#include "stm32f10x.h" // Device header

void PWM_Init(void)

{

RCC_APB1PeriphClockCmd(RCC_APB1Periph_TIM2, ENABLE);

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA, ENABLE);

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_PP;

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_1; //GPIO_Pin_15;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(GPIOA, &GPIO_InitStructure);

TIM_TimeBaseInitTypeDef TIM_TimeBaseInitStructure;

TIM_TimeBaseInitStructure.TIM_ClockDivision = TIM_CKD_DIV1;

TIM_TimeBaseInitStructure.TIM_CounterMode = TIM_CounterMode_Up;

TIM_TimeBaseInitStructure.TIM_Period = 20000 - 1; //ARR

TIM_TimeBaseInitStructure.TIM_Prescaler = 72 - 1; //PSC

TIM_TimeBaseInitStructure.TIM_RepetitionCounter = 0;

TIM_TimeBaseInit(TIM2, &TIM_TimeBaseInitStructure);

TIM_OCInitTypeDef TIM_OCInitStructure;

TIM_OCStructInit(&TIM_OCInitStructure);

TIM_OCInitStructure.TIM_OCMode = TIM_OCMode_PWM1;

TIM_OCInitStructure.TIM_OCPolarity = TIM_OCPolarity_High;

TIM_OCInitStructure.TIM_OutputState = TIM_OutputState_Enable;

TIM_OCInitStructure.TIM_Pulse = 0; //CCR

TIM_OC2Init(TIM2, &TIM_OCInitStructure);

TIM_Cmd(TIM2,ENABLE);

}

void PWM_SetCompare2(uint16_t Compare) //变为通道2

{

TIM_SetCompare2(TIM2,Compare);

}

Servo.c

#include "stm32f10x.h" // Device header

#include "PWM.h"

void Servo_Init(void)

{

PWM_Init();

}

void Servo_SetAngle(float Angle) //参数为浮点型,方便写入

{

PWM_SetCompare2(Angle / 180 * 2000 + 500);

}

main.c

#include "stm32f10x.h" // Device header

#include "Delay.h"

#include "OLED.h"

#include "Servo.h"

#include "Key.h"

uint8_t KeyNum;

float Angle;

int main(void)

{

OLED_Init();

Servo_Init();

Init_KEY();

OLED_ShowString(1, 1, "Angle:");

while (1)

{

KeyNum = Key_Getnum();

if (KeyNum == 1)

{

Angle += 30;

if (Angle > 180)

{

Angle = 0;

}

}

Servo_SetAngle(Angle);

OLED_ShowNum(1, 7, Angle, 3);

}

}

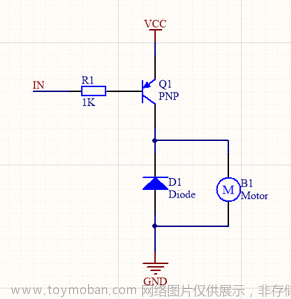

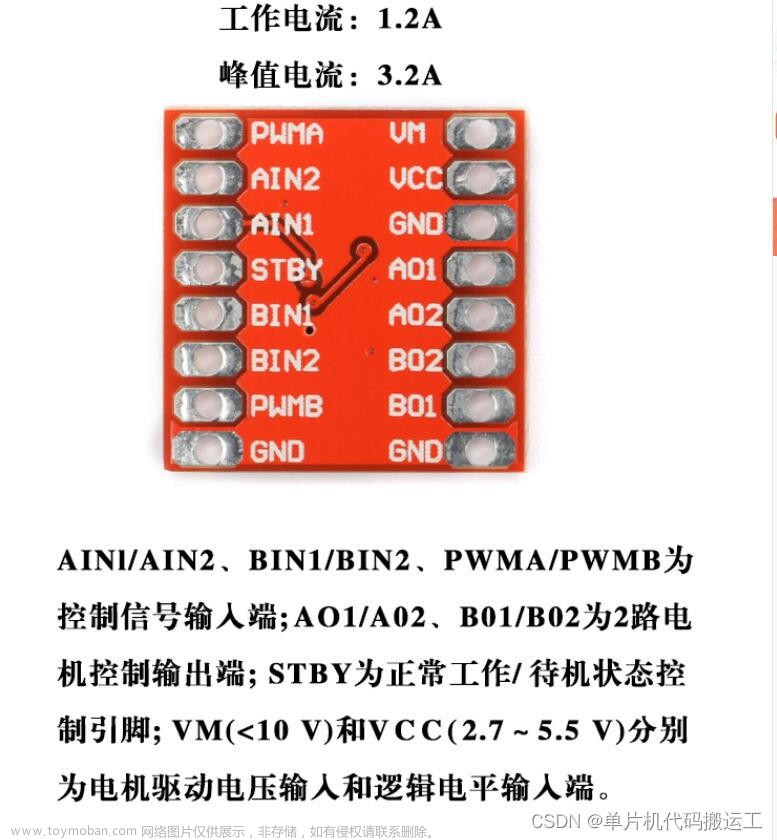

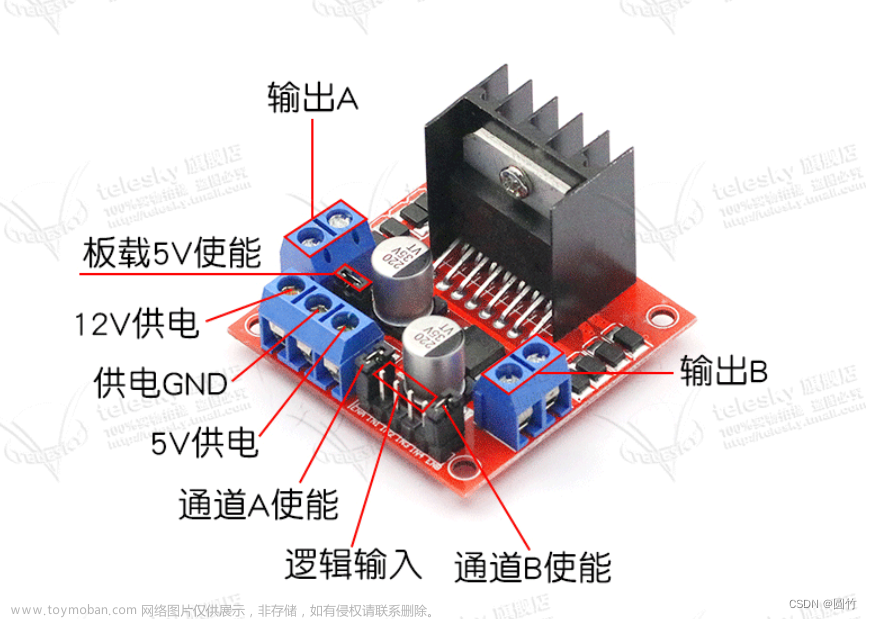

3.PWM驱动直流电机

pwm.c

#include "stm32f10x.h" // Device header

void PWM_Init(void)

{

RCC_APB1PeriphClockCmd(RCC_APB1Periph_TIM2, ENABLE);

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA, ENABLE);

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_PP;

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_2; //GPIO_Pin_15;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(GPIOA, &GPIO_InitStructure);

TIM_TimeBaseInitTypeDef TIM_TimeBaseInitStructure;

TIM_TimeBaseInitStructure.TIM_ClockDivision = TIM_CKD_DIV1;

TIM_TimeBaseInitStructure.TIM_CounterMode = TIM_CounterMode_Up;

TIM_TimeBaseInitStructure.TIM_Period = 100 - 1; //ARR

TIM_TimeBaseInitStructure.TIM_Prescaler = 36 - 1; //PSC

TIM_TimeBaseInitStructure.TIM_RepetitionCounter = 0;

TIM_TimeBaseInit(TIM2, &TIM_TimeBaseInitStructure);

TIM_OCInitTypeDef TIM_OCInitStructure;

TIM_OCStructInit(&TIM_OCInitStructure);

TIM_OCInitStructure.TIM_OCMode = TIM_OCMode_PWM1;

TIM_OCInitStructure.TIM_OCPolarity = TIM_OCPolarity_High;

TIM_OCInitStructure.TIM_OutputState = TIM_OutputState_Enable;

TIM_OCInitStructure.TIM_Pulse = 0; //CCR

TIM_OC3Init(TIM2, &TIM_OCInitStructure);

TIM_Cmd(TIM2,ENABLE);

}

void PWM_SetCompare3(uint16_t Compare)

{

TIM_SetCompare3(TIM2,Compare);

}

Motor.c文章来源:https://www.toymoban.com/news/detail-765471.html

#include "stm32f10x.h" // Device header

#include "PWM.h"

void Motor_Init(void)

{

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA, ENABLE);

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_Out_PP;

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_4 | GPIO_Pin_5;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;

GPIO_Init(GPIOA, &GPIO_InitStructure);

PWM_Init();

}

void Motor_SetSpeed(int8_t Speed)

{

if (Speed >= 0)//正转

{

GPIO_SetBits(GPIOA, GPIO_Pin_4);

GPIO_ResetBits(GPIOA, GPIO_Pin_5);

PWM_SetCompare3(Speed);

}

else

{

GPIO_ResetBits(GPIOA, GPIO_Pin_4);//反转

GPIO_SetBits(GPIOA, GPIO_Pin_5);

PWM_SetCompare3(-Speed);

}

}

main.c文章来源地址https://www.toymoban.com/news/detail-765471.html

#include "stm32f10x.h" // Device header

#include "Delay.h"

#include "OLED.h"

#include "Motor.h"

#include "Key.h"

uint8_t KeyNum;

int8_t Speed;

int main(void)

{

OLED_Init();

Motor_Init();

Init_KEY();

OLED_ShowString(1, 1, "Speed:");

while (1)

{

KeyNum = Key_Getnum();

if (KeyNum == 1)

{

Speed += 20;

if (Speed > 100)

{

Speed = -100;

}

}

Motor_SetSpeed(Speed);

OLED_ShowSignedNum(1, 7, Speed, 3);

}

}

到了这里,关于stm32——pwm驱动LED灯、舵机、直流电机的文章就介绍完了。如果您还想了解更多内容,请在右上角搜索TOY模板网以前的文章或继续浏览下面的相关文章,希望大家以后多多支持TOY模板网!