前言

INA219 是一款具备 I2C 或 SMBUS 兼容接口的分流器和功率监测计。该器件监测分流器电压降和总线电源电压,转换次数和滤波选项可通过编程设定。可编程校准值与内部乘法器相结合,支持直接读取电流值(单位:安培)。通过附加乘法寄存器可计算功率(单位:瓦)。I2C 或 SMBUS 兼容接口 具有 16 个可编程地址。

INA219 可在 0V 至 26V 范围内感测总线中的分压。该器件由 3V 至 5.5V 单电源供电,电源的最大流耗为1mA。INA219 的工作温度范围为 -40°C 至 125°C。

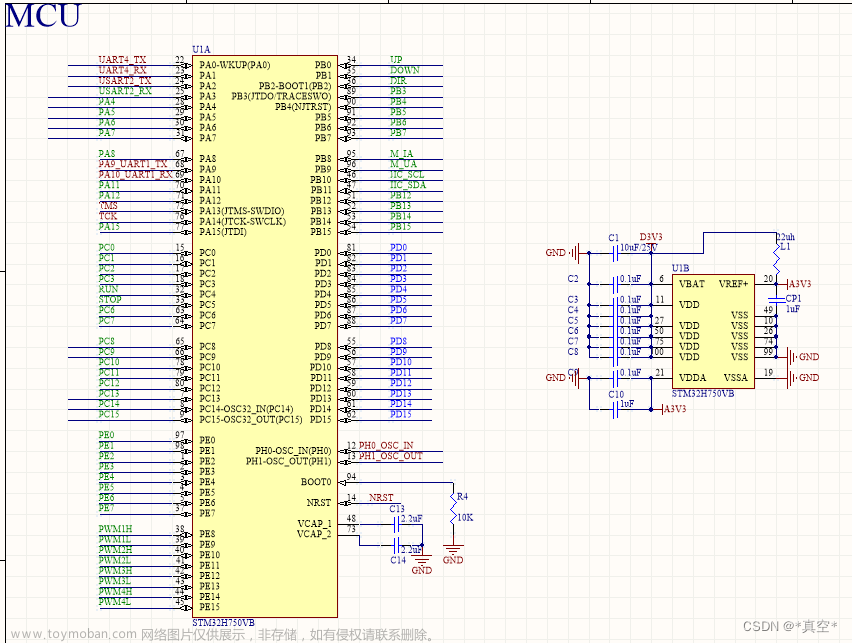

1 原理图

2 IIC地址说明

此测试时A0、A1都下拉接地,所以INA219的IIC通信地址为1000000B

3 寄存器地址说明

- 0x00 配置寄存器,用来配置工作模式、采集范围以及其他参数

- 0x01 分流电阻两端的电压

- 0x02 总线电压(IN-到GND的电压差)

- 0x03 功率

- 0x04 经过分流电阻两端的电流

- 0x05 校准寄存器,用于对测量结果进行校准

4 开始工作前配置

- 0x00 寄存器Bit 13:设置检测最大检测电压 0 = 16V,1 = 32V (此处项目需要测3V到5V的电压,故设置Bit 13 为 0)

- 0x00 寄存器Bit 11-12:设置总线分流电阻最大的电压(此处项目需要测0A到5A的电流,故设置Bit 11-12 为 01,即量程±80mV,可测电流±8A)

- 0x00 寄存器Bit 0-2:设置工作模式(默认)

- 0x05 寄存器:设置基准值(根据需要测的电压、电流范围再套入公式得出结果)

由以下公式可得出0x05的配置值。

C

a

l

=

t

r

u

n

c

(

0.04096

C

u

r

r

e

n

t

L

S

B

×

R

s

h

u

n

t

)

Cal = trunc\left ( \frac{0.04096}{CurrentLSB\times Rshunt} \right )

Cal=trunc(CurrentLSB×Rshunt0.04096)

C

u

r

r

e

n

t

L

S

B

=

M

a

x

i

m

u

m

E

x

p

e

c

t

e

d

C

u

r

r

e

n

t

2

15

CurrentLSB = \frac{Maximum Expected Current}{2^{15}}

CurrentLSB=215MaximumExpectedCurrent文章来源:https://www.toymoban.com/news/detail-767719.html

数据手册说明文档 文章来源地址https://www.toymoban.com/news/detail-767719.html

文章来源地址https://www.toymoban.com/news/detail-767719.html

5 程序代码

1)驱动程序

#include "main.h"

#include "ina219aidcnr_helper.h"

uint16_t ina219_calibrationValue;

uint16_t ina219_currentDivider_mA;

float ina219_powerMultiplier_mW;

/**

* @brief The IIC reads 16bit data from the specified register address.

* @param ina219 Slave configuration structure of the IIC.

* @param registerAddress Internal memory address.

* @return 16 bit register data.

*/

uint16_t INA219_ReadDataForRegister_16Bits(INA219_t *ina219, uint8_t registerAddress)

{

uint8_t Value[2];

HAL_I2C_Mem_Read(ina219->ina219_i2c, (INA219_ADDRESS<<1), registerAddress, 1, Value, 2, 1000);

return ((Value[0] << 8) | Value[1]);

}

/**

* @brief Writes 16 bits of data to the register.

* @param ina219 Slave configuration structure of the IIC.

* @param registerAddress Internal memory address.

* @param Value 16 bits of data to be written.

*/

void INA219_WriteDataToRegister_16Bits(INA219_t *ina219, uint8_t registerAddress, uint16_t Value)

{

uint8_t regAddr[2];

/* High Byte */

regAddr[0] = (Value >> 8) & 0xff;

/* Low Byte */

regAddr[1] = (Value >> 0) & 0xff;

HAL_I2C_Mem_Write(ina219->ina219_i2c, (INA219_ADDRESS<<1), registerAddress, 1, (uint8_t*)regAddr, 2, 1000);

}

/**

* @brief Read bus voltage.

* @param ina219 Slave configuration structure of the IIC.

* @return Read voltage value, unit mV.

*/

uint16_t INA219_ReadBusVoltage(INA219_t *ina219)

{

uint16_t result = INA219_ReadDataForRegister_16Bits(ina219, INA219_REG_BUS_VOLTAGE);

/* return mV */

return ((result >> 3 ) * 4);

}

/**

* @brief Read current register value.

* @param ina219 Slave configuration structure of the IIC.

* @return Current register value.

*/

uint16_t INA219_ReadCurrentRaw(INA219_t *ina219)

{

uint16_t result = INA219_ReadDataForRegister_16Bits(ina219, INA219_REG_CURRENT);

return (result);

}

/**

* @brief Read current register value, unit mA.

* @param ina219 Slave configuration structure of the IIC.

* @return Current value.

*/

uint16_t INA219_ReadCurrent_mA(INA219_t *ina219)

{

uint16_t result = INA219_ReadCurrentRaw(ina219);

return (result / ina219_currentDivider_mA);

}

/**

* @brief Read current register value, unit mV.

* @param ina219 Slave configuration structure of the IIC.

* @return Shunt Voltage value.

*/

uint16_t INA219_ReadShuntVoltage_mV(INA219_t *ina219)

{

uint16_t result = INA219_ReadDataForRegister_16Bits(ina219, INA219_REG_SHUNT_VOLTAGE);

/* When multiple sign bits are present, they will all be the same value.

* Negative numbers are represented in 2's complement format.

* Generate the 2's complement of a negative number by complementing the absolute value binary number and adding 1.

* Extend the sign, denoting a negative number by setting the MSB = 1.

* Extend the sign to any additional sign bits to form the 16-bit word. */

if(result > MAX_SHUNT_RANGE)

{

result = 65536 - MAX_SHUNT_RANGE;

}

/* Shunt voltage, unit mV. */

return (result / 100);

}

/**

* @brief INA219 system reset.

* @param ina219 Slave configuration structure of the IIC.

*/

void INA219_Reset(INA219_t *ina219)

{

INA219_WriteDataToRegister_16Bits(ina219, INA219_REG_CONFIG, INA219_CONFIG_RESET);

HAL_Delay(1);

}

/**

* @brief Set calibration register.

* @param ina219 Slave configuration structure of the IIC.

* @param calibrationData Calibrated data.

*/

void INA219_SetCalibration(INA219_t *ina219, uint16_t calibrationData)

{

INA219_WriteDataToRegister_16Bits(ina219, INA219_REG_CALIBRATION, calibrationData);

}

/**

* @brief Gets the value of the configuration register.

* @param ina219 Slave configuration structure of the IIC.

* @return Configuration Register value.

*/

uint16_t INA219_GetConfigInfo(INA219_t *ina219)

{

uint16_t result = INA219_ReadDataForRegister_16Bits(ina219, INA219_REG_CONFIG);

return result;

}

/**

* @brief Set configuration register.

* @param ina219 Slave configuration structure of the IIC.

* @param configData Configuration data.

*/

void INA219_SetConfig(INA219_t *ina219, uint16_t configData)

{

INA219_WriteDataToRegister_16Bits(ina219, INA219_REG_CONFIG, configData);

}

/**

* @brief The measurement results are calibrated. Voltage range is 16V, Current range is 8A.

* @param ina219 Slave configuration structure of the IIC.

*/

void INA219_SetCalibration_16V_8A(INA219_t *ina219)

{

uint16_t configInfo = INA219_CONFIG_VOLTAGE_RANGE_16V |

INA219_CONFIG_GAIN_2_80MV | INA219_CONFIG_BADCRES_12BIT |

INA219_CONFIG_SADCRES_12BIT_1S_532US |

INA219_CONFIG_MODE_SANDBVOLT_CONTINUOUS;

// Current_LSB = Maximum Expected Current / 2^15 = (80 / 10) / 2^15 = 0.0002

// Cal = 0.04096 / (Current_LSB / R) = 0.04096 / (0.0002A * 0.01R) = 20480 = 0x5000

// Calibration Register = 20480

ina219_calibrationValue = 20480;

// 1mA = Current_LSB * bits = 200uA * 5bit (5 bit/mA)

ina219_currentDivider_mA = 5;

// 1mW = Power_LSB * bits = 4mW * 0.25bit (0.25f bit/mW)

ina219_powerMultiplier_mW = 0.25f;

INA219_SetCalibration(ina219, ina219_calibrationValue);

INA219_SetConfig(ina219, configInfo);

}

/**

* @brief Ina219 driver initialization

* @param ina219 Slave configuration structure of the IIC.

* @param i2c Pointer to a I2C_HandleTypeDef structure that contains

* the configuration information for the specified I2C.

* @param Address Configuration data.

* @return status.

*/

uint8_t INA219_Init(INA219_t *ina219, I2C_HandleTypeDef *i2c, uint8_t Address)

{

ina219->ina219_i2c = i2c;

ina219->Address = Address;

ina219_currentDivider_mA = 0;

ina219_powerMultiplier_mW = 0;

uint8_t ina219_isReady = HAL_I2C_IsDeviceReady(i2c, (Address << 1), 3, 2);

if(ina219_isReady == HAL_OK)

{

INA219_Reset(ina219);

INA219_SetCalibration_16V_8A(ina219);

return 1;

}

else

{

return 0;

}

}

2)头文件

#ifndef INA219AIDCNR_HELPER_H

#define INA219AIDCNR_HELPER_H

#define INA219_ADDRESS (0x40)

#define MAX_SHUNT_RANGE (0x0FA0)

/* Register */

#define INA219_REG_CONFIG (0x00)

#define INA219_REG_SHUNT_VOLTAGE (0x01)

#define INA219_REG_BUS_VOLTAGE (0x02)

#define INA219_REG_POWER (0x03)

#define INA219_REG_CURRENT (0x04)

#define INA219_REG_CALIBRATION (0x05)

//

#define INA219_CONFIG_RESET (0x8000)

//

#define INA219_CONFIG_VOLTAGE_RANGE_16V (0x0000) // 0-16V Range

#define INA219_CONFIG_VOLTAGE_RANGE_32V (0x2000) // 0-32V Range

#define INA219_CONFIG_GAIN_1_40MV (0x0000) // Gain 1, 40mV Range

#define INA219_CONFIG_GAIN_2_80MV (0x0800) // Gain 2, 80mV Range

#define NA219_CONFIG_GAIN_4_160MV (0x1000) // Gain 4, 160mV Range

#define INA219_CONFIG_GAIN_8_320MV (0x1800) // Gain 8, 320mV Range

#define INA219_CONFIG_BADCRES_9BIT (0x0000) // 9-bit bus res = 0..511

#define INA219_CONFIG_BADCRES_10BIT (0x0080) // 10-bit bus res = 0..1023

#define INA219_CONFIG_BADCRES_11BIT (0x0100) // 11-bit bus res = 0..2047

#define INA219_CONFIG_BADCRES_12BIT (0x0180) // 12-bit bus res = 0..4097

#define INA219_CONFIG_BADCRES_12BIT_2S_1060US (0x0480) // 2 x 12-bit bus samples averaged together

#define INA219_CONFIG_BADCRES_12BIT_4S_2130US (0x0500) // 4 x 12-bit bus samples averaged together

#define INA219_CONFIG_BADCRES_12BIT_8S_4260US (0x0580) // 8 x 12-bit bus samples averaged together

#define INA219_CONFIG_BADCRES_12BIT_16S_8510US (0x0600) // 16 x 12-bit bus samples averaged together

#define INA219_CONFIG_BADCRES_12BIT_32S_17MS (0x0680) // 32 x 12-bit bus samples averaged together

#define INA219_CONFIG_BADCRES_12BIT_64S_34MS (0x0700) // 64 x 12-bit bus samples averaged together

#define INA219_CONFIG_BADCRES_12BIT_128S_69MS (0x0780) // 128 x 12-bit bus samples averaged together

#define INA219_CONFIG_SADCRES_9BIT_1S_84US (0x0000) // 1 x 9-bit shunt sample

#define INA219_CONFIG_SADCRES_10BIT_1S_148US (0x0008) // 1 x 10-bit shunt sample

#define INA219_CONFIG_SADCRES_11BIT_1S_276US (0x0010) // 1 x 11-bit shunt sample

#define INA219_CONFIG_SADCRES_12BIT_1S_532US (0x0018) // 1 x 12-bit shunt sample

#define INA219_CONFIG_SADCRES_12BIT_2S_1060US (0x0048) // 2 x 12-bit shunt samples averaged together

#define INA219_CONFIG_SADCRES_12BIT_4S_2130US (0x0050) // 4 x 12-bit shunt samples averaged together

#define INA219_CONFIG_SADCRES_12BIT_8S_4260US (0x0058) // 8 x 12-bit shunt samples averaged together

#define INA219_CONFIG_SADCRES_12BIT_16S_8510US (0x0060) // 16 x 12-bit shunt samples averaged together

#define INA219_CONFIG_SADCRES_12BIT_32S_17MS (0x0068) // 32 x 12-bit shunt samples averaged together

#define INA219_CONFIG_SADCRES_12BIT_64S_34MS (0x0070) // 64 x 12-bit shunt samples averaged together

#define INA219_CONFIG_SADCRES_12BIT_128S_69MS (0x0078) // 128 x 12-bit shunt samples averaged together

#define INA219_CONFIG_MODE_MASK 0x07

#define INA219_CONFIG_MODE_POWERDOWN 0x00

#define INA219_CONFIG_MODE_SVOLT_TRIGGERED 0x01

#define INA219_CONFIG_MODE_BVOLT_TRIGGERED 0x02

#define INA219_CONFIG_MODE_SANDBVOLT_TRIGGERED 0x03

#define INA219_CONFIG_MODE_ADCOFF 0x04

#define INA219_CONFIG_MODE_SVOLT_CONTINUOUS 0x05

#define INA219_CONFIG_MODE_BVOLT_CONTINUOUS 0x06

#define INA219_CONFIG_MODE_SANDBVOLT_CONTINUOUS 0x07

typedef struct

{

I2C_HandleTypeDef *ina219_i2c;

uint8_t Address;

} INA219_t;

uint8_t INA219_Init(INA219_t *ina219, I2C_HandleTypeDef *i2c, uint8_t Address);

uint16_t INA219_ReadBusVoltage(INA219_t *ina219);

uint16_t INA219_ReadCurrent_mA(INA219_t *ina219);

uint16_t INA219_ReadCurrent_raw(INA219_t *ina219);

uint16_t INA219_ReadShuntVoltage_mV(INA219_t *ina219);

uint16_t INA219_ReadDataForRegister_16Bits(INA219_t *ina219, uint8_t registerAddress);

uint16_t INA219_GetConfigInfo(INA219_t *ina219);

void INA219_Reset(INA219_t *ina219);

void INA219_SetCalibration(INA219_t *ina219, uint16_t calibrationData);

void INA219_SetConfig(INA219_t *ina219, uint16_t configData);

void INA219_SetCalibration_16V_8A(INA219_t *ina219);

void INA219_WriteDataToRegister_16Bits(INA219_t *ina219, uint8_t registerAddress, uint16_t Value);

#endif //INA219AIDCNR_HELPER_H

3) 测试代码

int main(void)

{

/* USER CODE BEGIN 1 */

uint16_t vbus, vshunt, current;

/* USER CODE END 1 */

/* MCU Configuration--------------------------------------------------------*/

/* Reset of all peripherals, Initializes the Flash interface and the Systick. */

HAL_Init();

/* USER CODE BEGIN Init */

/* USER CODE END Init */

/* Configure the system clock */

SystemClock_Config();

/* USER CODE BEGIN SysInit */

/* USER CODE END SysInit */

/* Initialize all configured peripherals */

MX_GPIO_Init();

MX_USART1_UART_Init();

MX_I2C2_Init();

/* USER CODE BEGIN 2 */

while(!INA219_Init(&ina219, &hi2c2, INA219_ADDRESS))

{

}

/* USER CODE END 2 */

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

vbus = INA219_ReadBusVoltage(&ina219);

vshunt = INA219_ReadShuntVoltage_mV(&ina219);

current = INA219_ReadCurrent_mA(&ina219);

sprintf(strBuffer, "INA219 param: vbus:%d mV; current:%d mA\r\n", vbus, current);

HAL_UART_Transmit(&huart1, strBuffer, strlen(strDataBuf), 0xff);

UserDelay_ms(500);

}

到了这里,关于【STM32 开发】| INA219采集电压、电流值的文章就介绍完了。如果您还想了解更多内容,请在右上角搜索TOY模板网以前的文章或继续浏览下面的相关文章,希望大家以后多多支持TOY模板网!